DESCRIPTION

The two most widely used types of powder coating are TGIC Polyester and Urethane Polyester. Both types of powder coating provide excellent wear resistance and outdoor durability. Noise barrier powder coating provides excellent chemical resistance. This powder coating system is often seen in the highway noise barrier powder coating. Polyester urethane powder typically needs to undergo a higher temperature curing cycle, which limits its ability to be applied to low-cure candidates, such as aluminum extruded parts, cast parts and lead based parts. Another limitation of polyester urethanes is that they are limited to thin film applications of 1-3 mils (25-75µm). As a thickness increases, the film has the tendency pull back on itself which can produce an "orange-peel" effect.

Similar to Polyester Urethane Powders, TGIC Polyester powders are often used in power transmission and automotive industries. TGIC Polyester powder coating films on the other hand can be applied with greater ease as they can be sprayed at thickness greater than 3 mils (>75µm). TGIC Polyester powders can also be cured at lower temperatures making them ideal for cast parts and extruded parts. TGIC-Polyester noise barrier powder coating is also very resistant to over baking, which is associated with a lower gloss and a yellow appearance; however, the chemical resistance of this powder coating system is reduced.

FEATURES

Strong adhesion strength: Resin content is reasonable, and it was added special rubber elastomer in the primer in the primer, so it has strong adhesion strength, if the construction technique is reasonable, no peeling off.

Good cracking resistance: Thermoplastic Paint marking is cracking resistance than normal paint.

Bright color: The paint adopts the color of the highest level with reasonable proportion, so it has good weather resistance and will not change color if long term exposure.

High usage ratio: The major feature of paint is low density, big volume and high usage ratio.

Good dirt resistance: The dosage and quality of PE wax are the key point of impacting the dirt resistance. We use the high quality PE wax from Germany.

SPECIFICATION

Product details | |

Product Name | Pure polyester - Noise barrier powder coating |

Material | pure polyester |

Color | BLACK |

Surface Finish | smooth |

Gloss level | 2° |

Particle Size | Average 32-42μm |

Specific Gravity | 1.2-1.7g per cubic meter |

Coverage | 8-10 square meters per Kg at 60-90 μm film thickness |

film thickness | Not less than 100μm |

Powder coated Film Mechanical Properties | |

Adhesion | Cross-cut(2mm),no loss of adhesion |

Impact Resistance | Direct impact 50kg/cm |

Pencil Hardness | 1H-2H |

Cupping Test | 6mm Mandrel |

Bending Test | 5mm |

Powder Coated Film Chemical Resistance | |

Salt Spray Test | 5% NaCl Solution for 500 hours - No change |

Acid Resistance | 5% NaCl Solution for 500 hours - No change |

Alkali Resistance | 3% NaOH for 240 hours dip test - No change |

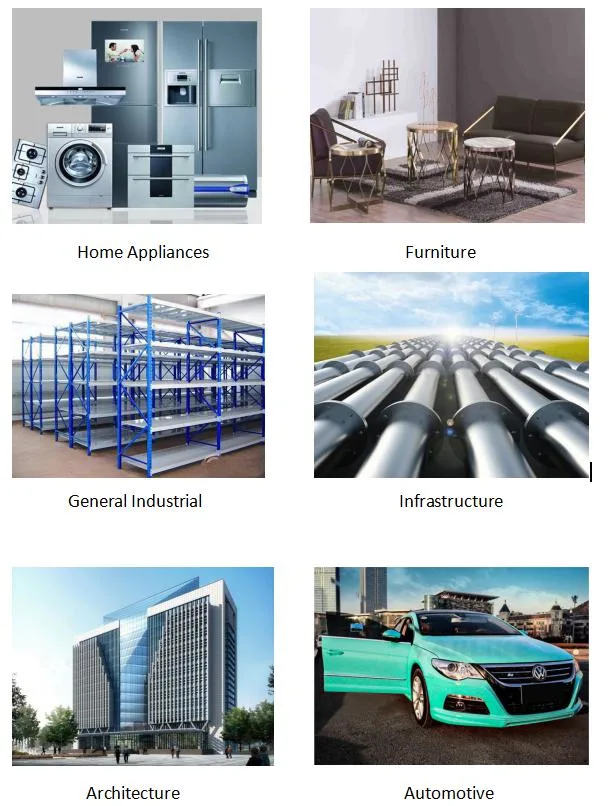

APPLICATIONS

PACKAGE AND DELIVERY

CERTIFICATES